Track, Detect & Fix Your Fleet

AI That Helps You Run Your Fleet Maintenance

How Fleet Maintenance Software Works (And How We Do It)

Predict the issue before it becomes a crisis

Send a mechanic to your yard

Book the repair automatically

Update records without you lifting a finger

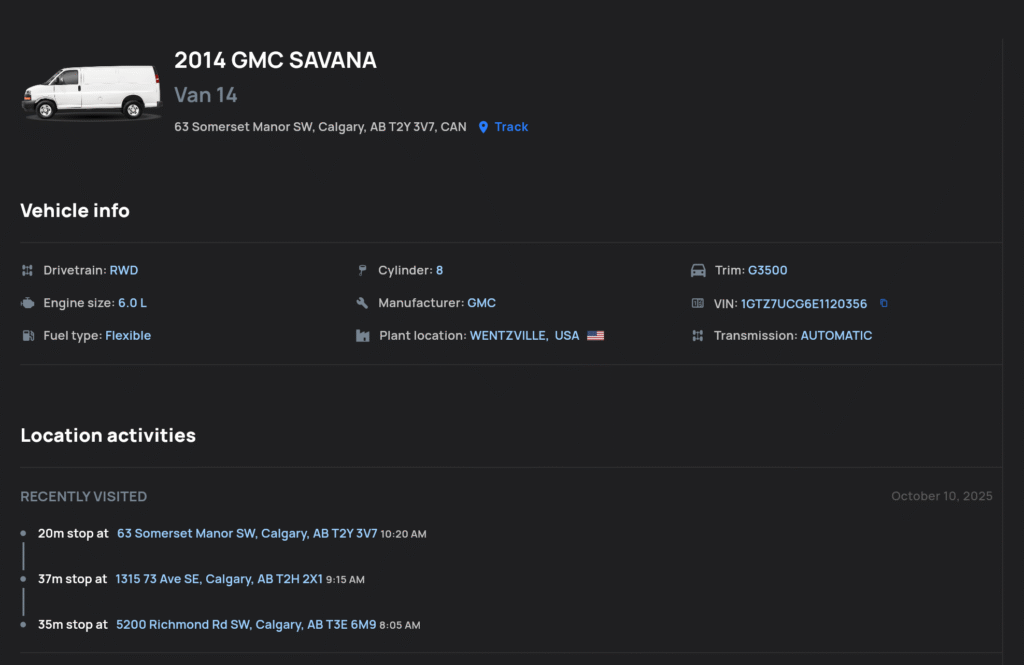

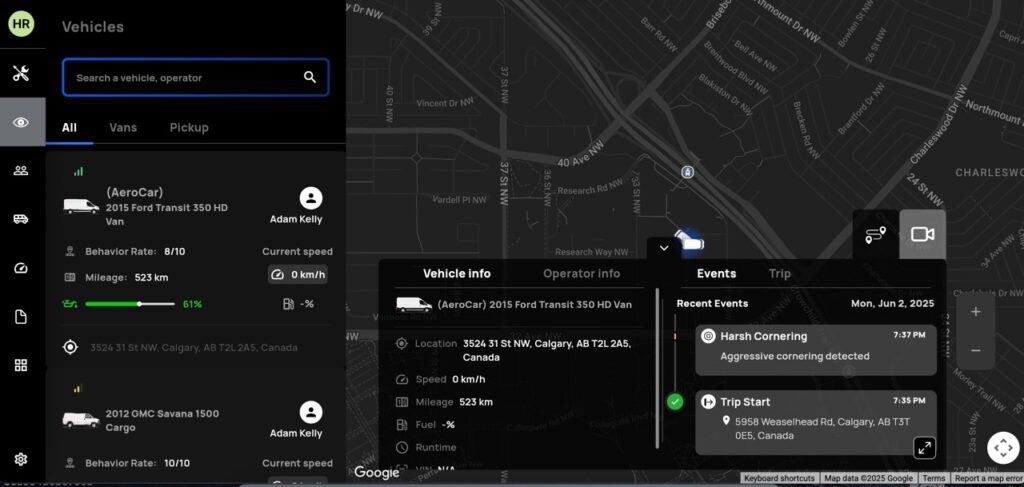

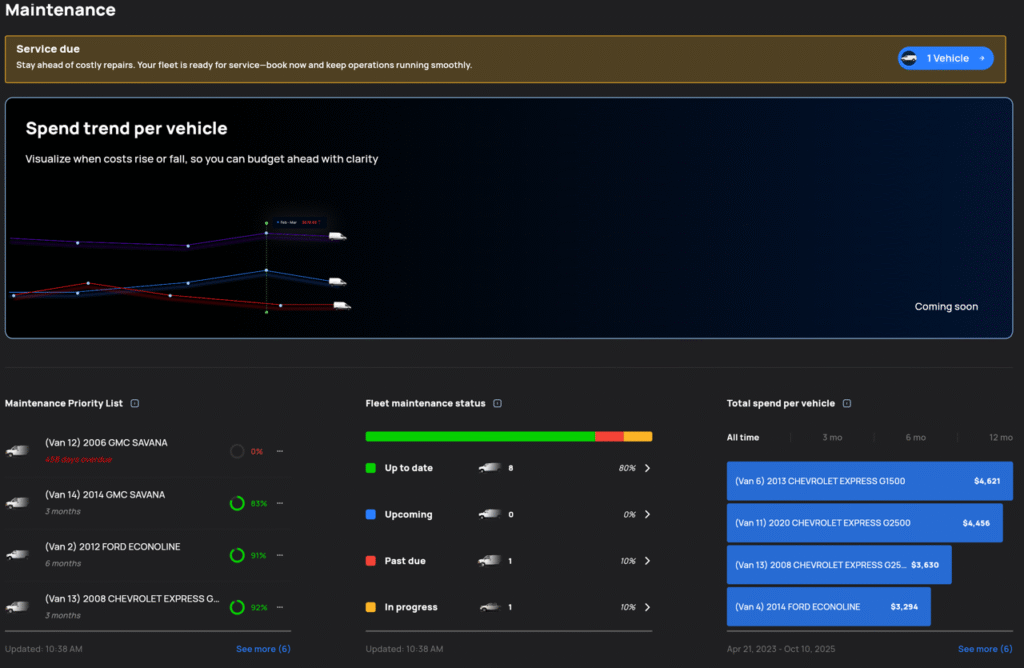

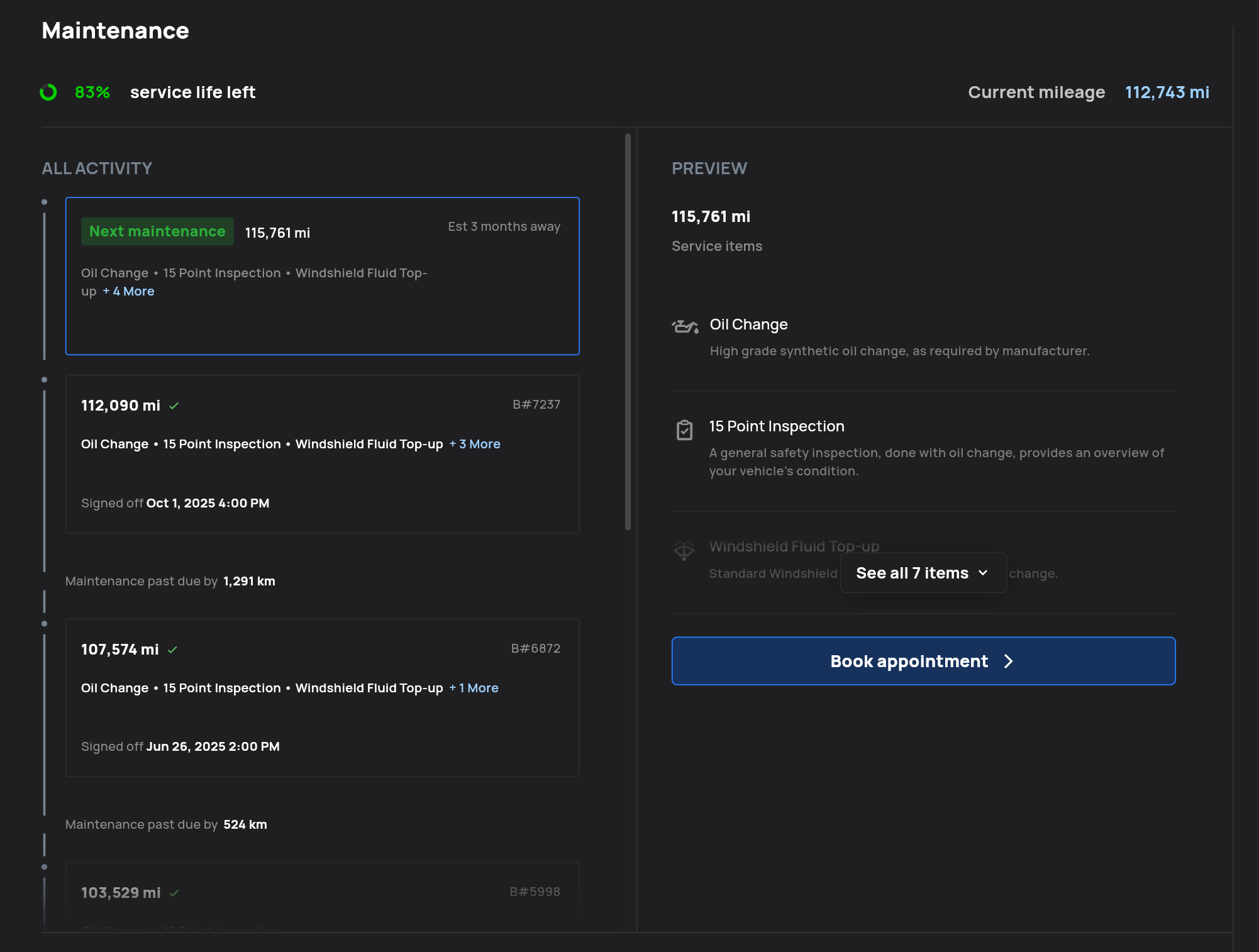

1. Monitor Vehicle Health in Real Time

- WiDrive installs WiLink OBD-II devices in your fleet vehicles.

- Tracks engine codes, fluid health, brake wear, and GPS location 24/7.

- Data flows to your dashboard—so you always know what’s happening.

2. Detect Problems Before They Break You

Our predictive fleet maintenance platform uses analytics to catch issues early: low oil life, worn brakes, electrical warnings.

- Predictive analytics catch issues early: low oil life, worn brakes, electrical warnings.

- The system estimates failure windows so you can act before it’s urgent.

- Stops $75 fixes from turning into $3,000 disasters.

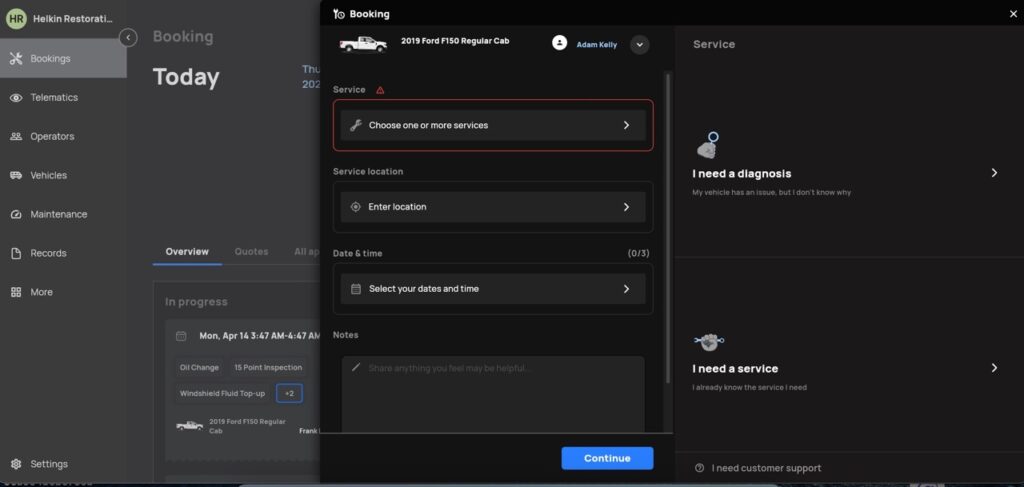

3. Automated Service Booking

- No phone tag, no waiting.

- When the system flags an issue, it auto-schedules a mechanic at your location.

- You choose preferred off-hours for zero disruption.

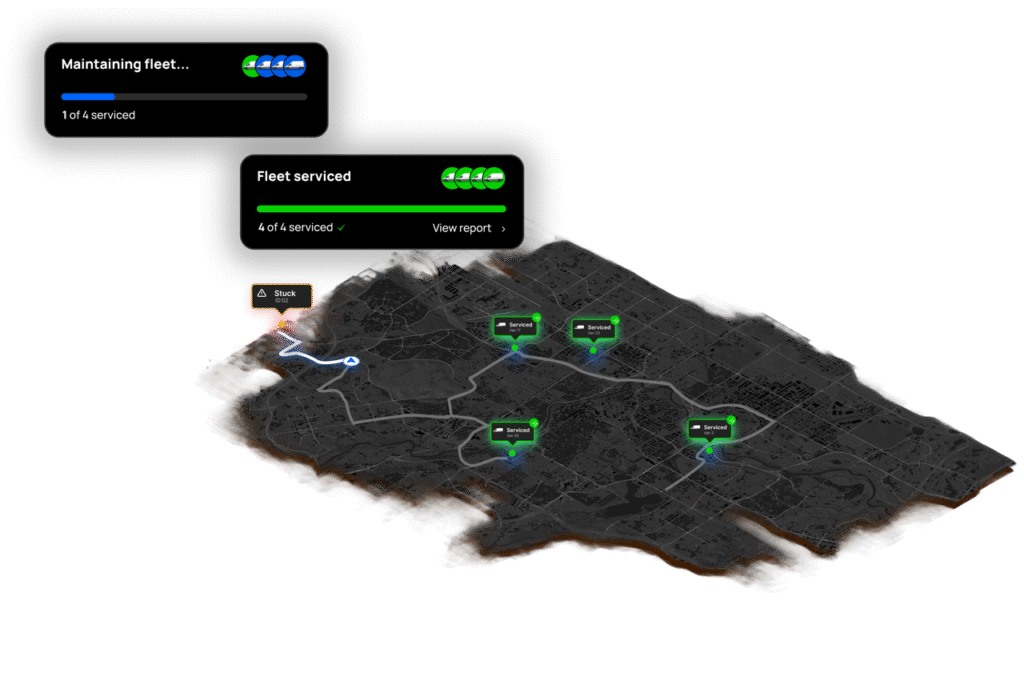

4. On-Site Repair Execution

- A certified mechanic arrives with everything needed.

- Handles 200+ repair types: oil, brakes, batteries, transmissions, A/C, electrical, diagnostics.

- Done in your yard—night, weekend, or whenever your trucks rest.

5. Full Digital Records & Analytics

- Every service is logged automatically: date, cost, parts, next due.

- Get compliance-ready reports and cost-per-vehicle insights.

- See which trucks eat the most budget—plan smarter.

Existed solutions just give you numbers and charts.

We actually show up and fix stuff. Right where your trucks are parked.

Our combination of fleet management automation and real mechanics saves a ton of time. Most clients see their trucks breaking down about 40% less often.

Keep Your Trucks Running. Cut Downtime. Save Thousands with Fleet Management Automation

According to FleetMaintenance, every idle truck is estimated to cost $600–1,000 CAD per day, including projected losses from missed routes, driver wages, and customer dissatisfaction.

WiDrive solves that with a predictive fleet maintenance platform that does more than monitor—it acts. We combine advanced analytics with on-site mechanics who show up before breakdowns happen.

join the success

Want to See This in Real Life?

Turn your maintenance mess into something that actually works.

Key Features That Make Us Different

The system’s not exactly rocket science, but it works. Trucks tell us when they’re hurting before they give up entirely. The computer handles the boring stuff – scheduling repairs and keeping records.

Best part? Everything happens right where your trucks sleep. No more watching drivers kill time at repair shops across town. When something breaks at 3 AM, there’s someone to call who’ll actually pick up.

Some fleets just can't mess around with downtime. We're talking about:

Calgary Fleets We Serve

HVAC

Those HVAC guys who need to reach frozen houses in February

Delivery

Delivery vans racing to hit their routes

Construction

Construction haulers moving equipment between sites

Utility Trucks

City trucks keeping the lights on and water flowing

Every truck that's not moving costs about $450 a day (and that's being nice about it). Think about a typical fleet with 15 vehicles. Without someone watching their backs, they'll probably hit about 10 nasty breakdowns a year. That means 30 days where trucks aren't making money - they're just eating cash.

Do the math: 30 days times 450 comes to 13,500 thrown away each year. And that's just the start. It doesn't count towing bills, rushed repairs, or customers finding someone else while your truck's dead on the side of Stoney Trail.

WiDrive typically cuts those surprise breakdowns by 40%. That's at least $5,400 staying in your pocket each year. Plus, you're saving on fuel (because well-maintained trucks run better), avoiding those painful towing bills, and keeping customers happy.

But here's the thing - it's not just about the money. It's about sleeping better knowing your fleet isn't going to leave you hanging when you need it most. That peace of mind? Pretty tough to put a price tag on that.

Real ROI: How Much Can You Save?

Let’s break down some real numbers, nothing fancy:

Real stories show how this stuff actually works in Calgary. Take that HVAC outfit last winter - system caught their brake pads wearing thin. Instead of finding out the hard way during morning rush hour, a tech swung by at 11 PM and knocked it out. Next day? Business as usual, no frozen customers waiting.

Or that delivery crew running Amazon routes - their system spotted a battery ready to give up. Got it swapped before dawn, saved them from explaining to Jeff Bezos why those packages weren't moving.

Then there's the construction guys - computer noticed hydraulic fluid getting low on their crane truck. Fixed it Saturday night while the machine was cold anyway. Monday morning? Crew shows up, crane's ready to roll. No site manager breathing down anyone's neck about delays.

Use Cases – How Fleets Benefit

Let’s break down some real numbers, nothing fancy:

Your questions answered

Common questions

Q. Can WiDrive work with mixed fleets?

A. Yes. Our system handles light vans, medium trucks, and specialized vehicles.

Q: Do I need to change my existing fleet software?

A. No. WiDrive integrates with most telematics platforms.

Q: How fast do you respond in Calgary?

A. Emergency repairs in under 2 hours on average.

Q: Can you service after hours?

A. Absolutely. Nights, weekends, and even holidays if required.

Q: How do you handle parts?

A. We stock common parts and source the rest through local Calgary suppliers.